[6.3.1A.2] 成果

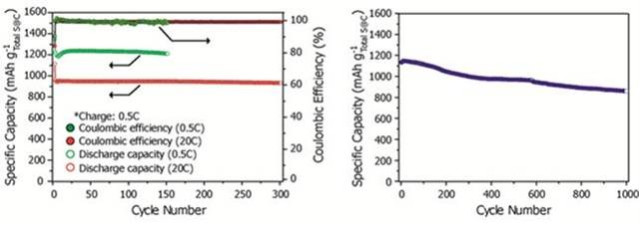

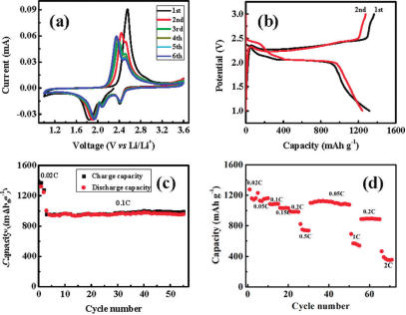

(1) 成果を図1に示す。

図1

(This figure is quoted from the document said above)

(2) 「電流レート」は「2C」である。

(3) ほぼ実用のレベルに達している。

(4) 「EV」の搭載して「試作車」を走らせてほしい。

[6.3.2A] 研究例(2A) New lithium/sulfur battery doubles energy density of lithium-ion

(Ⅵ) リチウム硫黄電池

[6.1] リチウム硫黄電池の概念

(1) 「リチウム硫黄二次電池」(以下「RLSB」という)は、空気電池以外では

最も「重量エネルギー密度」の高い二次電池である。

(2) 「硫黄」の「重量エネルギ密度」は「1675Wh/kg」と現行の「リチウム・イオン電池」の

「正極」のおよそ「200Wh/kg」と比較して非常に大きい。

(3) 「RLSB」は「負極」に「リチウム」、「正極」に単体の「硫黄」あるいは「硫黄化合物」を用いる二次電池である。

(4) 「正極」に用いる活物質の「硫黄」は安価であるから「RLSB」の低価格化を可能にする。

[6.2] 技術的な課題

[6.2.1] 正極の構造

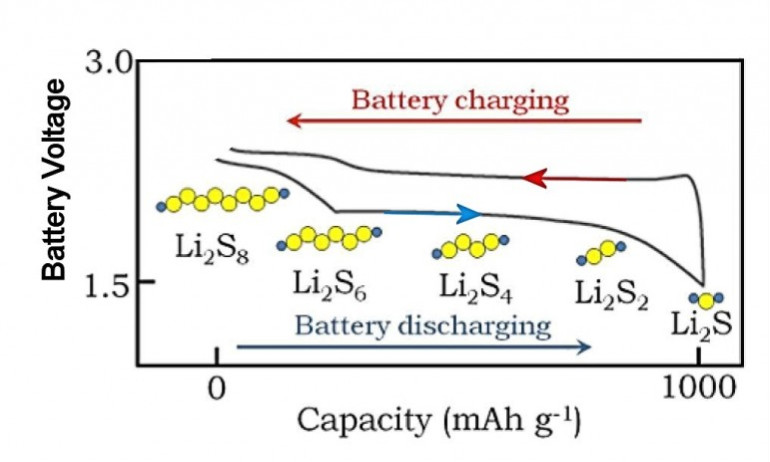

(1) 放電の過程において「正極」では「硫黄」と「リチウム・イオン」が

反応して中間的な「放電生成物」である「硫黄化合物」の「L2S8」、「L2S6」、「L2S4」、「L2S3」、「L2S2」、

「L2S」まで生成される。

(2) 「L2S2」までの「放電生成物」は「電解液」に溶出する。

(3) そして「負極」の「リチウム」と反応して「自己放電」を生じる。

(4) 「L2S」は「電解液」に溶出しないで「正極」に析出する。

(5) そこで「多硫化リチウム」を「電解液」に溶出させないように種々の技術が提案されている。

[6.2.2] 電解質

[6.2.2.1] 液体電解質

(1) 「リチウム・イオン電池」で用いられているような「有機電解液」では「多硫化リチウム」の溶出が生じる。

(2) [6.3.6] で紹介されている「イオン液体」を用いる研究例がある。

この電解質では「多硫化リチウム」の溶出が生じない。

[6.2.2.2] 固体電解質

(1) [6.3.7]で示す「オークリッジ・ナショナル研究所」の研究例では

「lithium polysulfidophosphates」 (a new class of sulfur-rich materials

with good electrical conductivity)

という「固体電解質」を使って、「60℃」で「300回」の充放電のサイクルの後に

「1200mAh/g」の

「正極」の容量を維持する成果が得られている。

(2) しかしこの「固体電解質」の相対的に低い「イオン伝導率」のせいで

「出力密度」は「リチウム・イオン電池」に比べて小さい。

[6.3] 研究例

[6.3.1A]

研究例(A1) 「KAIST」の研究 (2013.12.4)

[6.3.1A.1] リチウム硫黄電池のシステム

(1) リチウムイオンよりも長持ちする「リチウム硫黄二次電池」を開発。

(2) 従来よりエネルギー密度5倍以上向上…1000回の充放電にも容量維持。

(3) 「KAIST」(韓国科学技術院、カン・ソンモ総長)は「新素材工学科」の「キム・ドギョン教授」と

「EEWS」の「チェ・ジャンウク教授」が共同で、現在商用化されている

「リチウム・イオン電池」より寿命と「エネルギ密度」が向上した「リチウム硫黄二次電池」を

開発したと「2013年12月3日」に発表した。

(4) 今回開発された「リチウム硫黄二次電池」は「単位重量」当りの「エネルギ密度」が

最大で「2100Wh/kg」と、商用化されている「リチウム・イオン電池」

(最大387Wh/kg)の「5.4倍」に達する。

またこれまでに開発された「リチウム硫黄二次電池」とはちがい、「数百回」の充放電が可能。

(5) 研究チームは「ナノ電極材料合成技術」を活用して「厚さ75nm(ナノメートル)」

「長さ15μm(マイクロメートル)」の「硫黄ナノワイヤ」を垂直に整列して

電極材料を製造した。

(6) この「硫黄ナノワイヤ整列構造」は「1次元構造体」であり、電子の速い移動が

可能なため電極の伝導度が向上した。

(7) また「硫黄ナノワイヤ」の表面に均一に炭素をコーティングし「硫黄」と「電解液」が

直接接触しないことから、充放電中に「硫黄」が溶けることを防止、

「RLSB」のもつ寿命の短さという問題を解決した。

(8) これまでに開発されている「RLSB」用の「電極」は

最初は高い容量を示すものの充放電を繰り返すと容量が持続的に減少した。

(9) しかし今回開発された「電極」は速い放電速度(3分ごとに1回の充放電条件)で

「300回」の充放電の後でも最初の容量の「99.2%」を維持、

「1000回」の充放電の後に「70%以上」の容量を示した。

(10) 研究チームは関連技術について「韓国国内特許」1件と「PCT国際特許」1件を出願した。

(11) 「キム・ドギョン教授」は

「このリチウム硫黄電池は無人飛行機、電気自動車および再生エネルギー貯蔵装置などに必要な

次世代高性能二次電池の実現を早めるのに役立つだろう。

リチウム硫黄電池の問題だった寿命低下の解決方案を提示できた」

と話している。

(12) 研究結果はナノ素材分野の国際学術誌「Advanced

Materials」に12月3日付で掲載された。

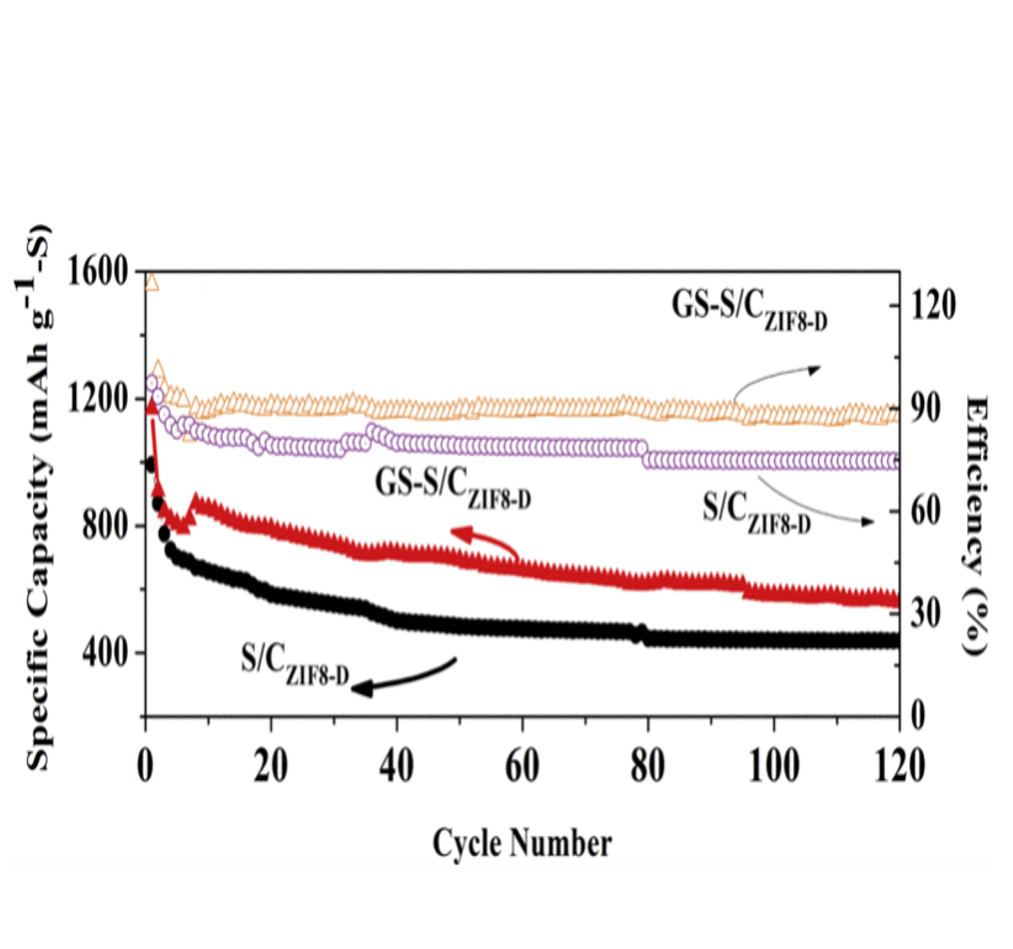

[6.3.1A.2] 成果

(1) 成果を図1に示す。

図1

(This figure is quoted from the

document said above)

(2) 「電流レート」は「2C」である。

(3) ほぼ実用のレベルに達している。

(4) 「EV」の搭載して「試作車」を走らせてほしい。

[6.3.2A] 研究例(2A) New

lithium/sulfur battery doubles energy density of lithium-ion

By Brian Dodson, Lawrence Berkeley Lab, December 1, 2013

[6.3.2A.1] 「RLSB」のシステム

(1) Batteries. We buy

them at the store, use them up, and throw them away without much thought.

(2) In reality, however, batteries are remarkably complex

electrochemical devices that are continually evolving.

(3) The latest

example of this comes from the Lawrence Berkeley National Laboratory,

where researchers have invented an advanced lithium/sulfur (Li/S) cell

that offers a unique combination

of energy storage, power, recharge

speed, and survivability.

(4) Lithium/sulfur

rechargeable batteries offer a remarkably large capacity for energy storage,

mainly because two electrons are produced each time a molecule is

processed through the battery's chemistry.

(5) The

voltage of a Li/S cell depends on the chemical entities in which electrical

energy is ...

(6) A basic Li/S cell consists of a lithium anode, a

carbon-sulfur cathode, and an electrolyte

that permits lithium ions to

pass.

(7) The overall cell reaction during discharge converts lithium

metal in the anode into Li2S

at the surface of the cathode.

(8) The flow of two lithium ions from the anode to the cathode is then

balanced

by the flow of two electrons between the battery contacts,

delivering double the current

of a Li-ion battery

at a voltage

between about 1.7 and 2.5 volts, depending on the state of charge of the cell.

(9) Lithium polysulfides are formed at intermediate charge levels,

which affect the cell voltage

as indicated above.

(10) That's

the good news. The bad news involves a host of materials problems associated

with the basic Li/S chemistry and some side reactions.

(11) When the sulfur in the cathode absorbs lithium ions from the

electrolyte, the Li2S has nearly

double the volume of the original

sulfur.

(12) This is a very large source of mechanical stress on the

cathode, which causes mechanical deterioration,

reduces the electrical

contact between the carbon and the sulfur

(the path whereby electrons

flow to allow the reaction to occur), and prevents the flow of lithium ions

to the sulfur surface.

(13) Another

problem is that lithium and sulfur generally don't react immediately to form

Li2S,

but rather get there through a series of intermediate species,

such as Li2S8, Li2S6, etc.

(14) Sulfur itself and Li2S are essentially

insoluble in the typical electrolyte used in Li/S cells,

but these

intermediate "polysulfides" often are soluble, which causes an ongoing

and severe loss of sulfur at the cathode.

(15) Other problems

appear, such as a roughening of the lithium anode surface with large charge

or discharge currents.

(16) All of these problems result in a

basic Li/S cell being a very bad battery.

(17) The

Li/S battery chemistry, however, offers the potential for such wonderful battery

performance that,

since its discovery in the 1960s, a lot of work has

been aimed at solving these problems.

(18) Engineers and scientists

have tried putting the sulfur inside nanochannels as well as

using

lithium-silicon-carbon alloy anodes, sulfur polymer cathodes, and a host of

other imaginative attempts at solving the interlocked Li/S battery

performance limitations.

(19) While a good deal of progress has been

made, development of a practical Li/S cell has eluded

researchers for

half a century.

(20) The

Lawrence Berkeley team addressed these problems by developing a nanocomposite

cathode

that addresses the three main problems presented by Li/S

cells.

(21) The new cathode material is a sulfur-graphene oxide

nanocomposite held together using an elastic polymer binder.

(22) Graphene

oxide is formed from graphite oxide by exfoliation, in which an ultrasonic field

is applied

to graphite oxide while suspended in water.

(23) The ultrasonic waves peel apart the layers of the graphite oxide,

producing very thin flakes of graphene oxide.

(24) These

flakes are then given a coating of sulfur a few nanometers in thickness.

(25) The thinness of the sulfur coating allows the sulfur atoms to make

good electrical contact

with the graphene oxide flakes.

(26) While not an excellent conductor of electricity, graphene oxide

has sufficient conductivity to

anchor the sulfur to the cathode,

thereby permitting a large flow of current to pass through the sulfur

layers.

(27) There

are intermediate products (lithium polysulfides) resulting from the operation of

a Li/S cell

that can dissolve into the ionic electrolyte of the cell,

thereby causing sulfur loss

and degrading the cell's storage capacity.

(28) One effect of putting the sulfur on the graphene oxide nanoflakes

is to protect one side

of the sulfur layer against this

degradation.

(29) In

the new Li/S cell, a protective surfactant is placed atop the sulfur layer to

also

protect its surface against dissolving in the electrolyte.

(30) Because the surfactant is cationic (attracted to the sulfur), it

will let the lithium anions through

to react with the sulfur of the

cathode while protecting the sulfur layer.

(31) As any lithium

polysulfides formed under the surfactant are trapped there, this addition nearly

eliminates the problem of sulfur loss.

(32) To

form a useful cathode for an Li/S cell, this loose collection of coated graphene

oxide nanoflakes

must be bound together to form a nanocomposite with a

very large surface area

that is accessible to the ionic electrolyte.

(33) Similar cells in the past have used 「polyvinylidene fluoride」, a

conducting polymer, as a binder material.

(34) However, such cells were

not able to long survive the enormous change in the volume of the sulfur layers

during charge and discharge of the cell.

(35) To ameliorate

this problem, the Berkeley team substituted an elastomeric co-polymer of

styrene butadiene rubber and carboxy methyl cellulose for the

binder.

(36) The electrolyte was also

changed in several ways from the traditional setup

(and this being

chemistry, you might need to brace yourself for some

challenging terminology here).

(37) While the same electrolyte salt

「(lithium bis(trifluoromethanesulfonyl)imide)」 was used,

the solvent was a

mixture of 「n-methyl-(n-butyl) pyrrolidinium bis(trifluoromethanesulfonyl)-imide

(PYR14TFSI)」,

「1,3-dioxolane (DOL), dimethoxyethane (DME)」

with 1 M

「lithium bis-(trifluoromethylsulfonyl)imide (LiTFSI)」, and 「lithium nitrate

(LiNO3)」.

(38) This

translates to combination which nicely balances the range of operating

temperature,

viscosity, and ionic conductivity required for efficient

Li/S cell operation.

(39) The tendency of the cell to form lithium

polysulfides was also reduced by the introduction

of the DOL and DME

fractions.

(40) The

lithium nitrate was added to reduce damage to the surface of the lithium metal

anode,

which had been observed to result from multiple charge/discharge

cycling.

(41) A traditional coated plastic separator (high porosity

polypropylene) was used to prevent

the flow of electrons through the

electrolyte while permitting free flow of the lithium ions.

(42) The result of these changes is greatly increased Li/S cell

performance.

(43) When the Li/S cell was charged and discharged at a

20-hour rate (C=0.05),

an initial specific energy of 500 Wh/kg (more

than twice that of Li-ion batteries) was still providing

as much energy

capacity as a fresh Li-ion battery after 1500 charge/discharge cycles.

(44) When the charge/discharge rate is increased to a one-hour rate

(C=1.0), the energy capacity

decreases by a factor of about 40-50

percent, but the cell continues to function well past 1,500 cycles.

(45) When

the Li/S cells were operated at very large power output

(C=6.0, meaning

that a cell would charge or discharge in 10 minutes) even after 150 cycles

the specific energy of the cell was larger than that of a fresh and

pampered Li-ion cell.

(46) This capability for very large power charge

and discharge was quite sensitive

to the amount of lithium nitrate

added to the electrolyte.

(47) The

potential price point for Li/S cells following the new design is potentially

as low as US$100/kWh of storage capacity.

(48) Beyond making

possible lithium/sulfur batteries with unprecedented specific energy, rate

capacity,

and long cycle life, many of the innovations made by the

Berkeley team may also be useful

in designing better and less expensive

Li-ion cells.

(49) The Li/S cell for the first time has demonstrated its

potential to challenge the dominant Li-ion battery

chemistry in the big

leagues of electric cars.

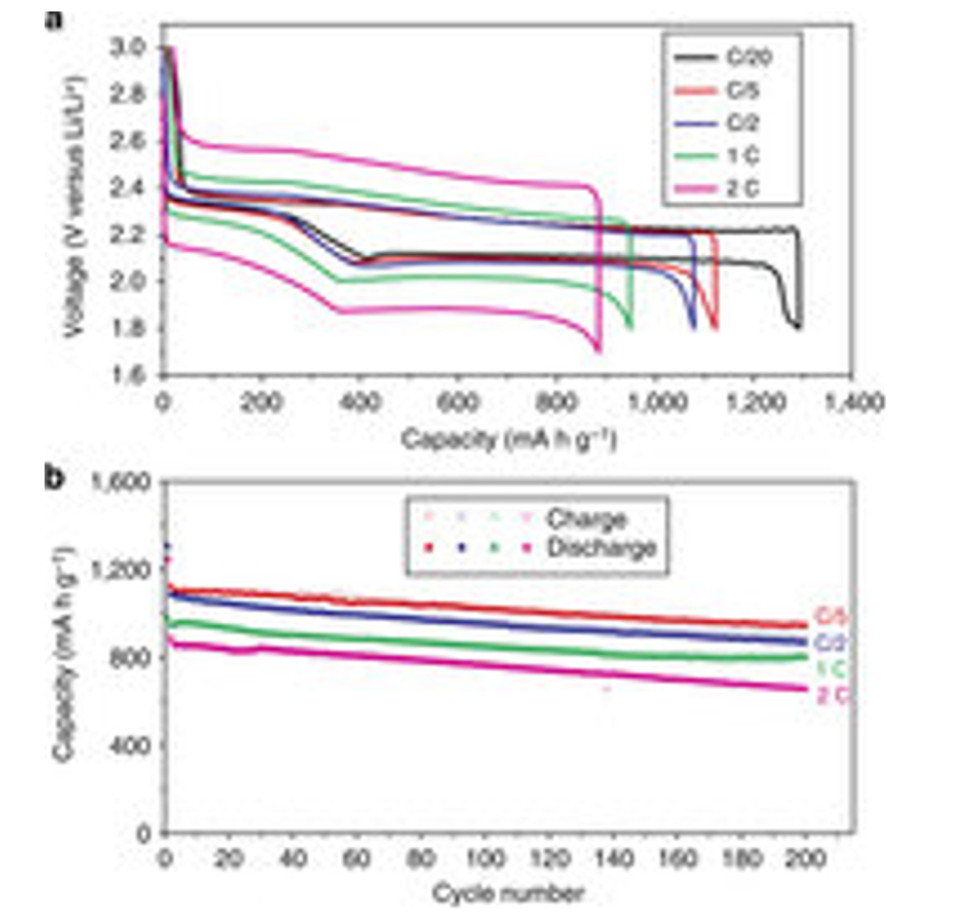

[6.3.2A.2] 成果

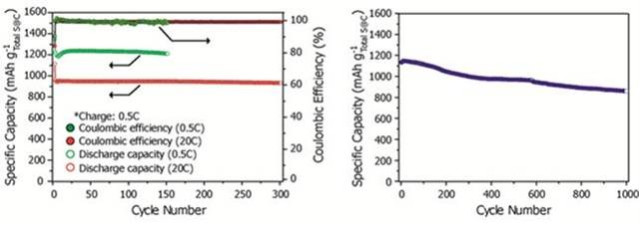

(1) 成果を図1、図2、図3に示す。

図1 A scanning electron micrograph of the nanostructure of the

cathode of a Berkeley Li/S cell

and a schematic of the layers in the structure ( Lawrence Berkeley Lab)

(This figure is quoted from the

document said above)

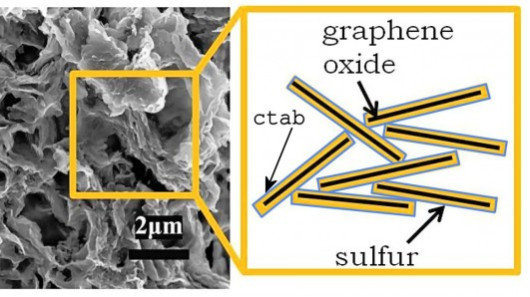

図2 Performance curves of a Berkeley Li/S cell. Charge/discharge voltage history

at extreme po...

(This figure is quoted from the

document said above)

図3

(This figure is quoted from the

document said above)

(2) 電流レート「2C」では「700mAh/g」の「容量」である。

(3) この「RLSB」を搭載した「EV」の試作車を走らせてほしい。

[6.3.3A] 研究例(3A)

Graphene Oxide as a Sulfur

Immobilizer in High Performance Lithium/Sulfur Cells

Liwen Ji(1), Mumin Rao(2), Haimei Zheng(3), Liang

Zhang(4), Yuanchang Li(5), Wenhui Duan(5),

Jinghua Guo(4), Elton J. Cairns(2), and Yuegang

Zhang(1)

(1)

The

Molecular Foundry, Lawrence Berkeley National Laboratory, Berkeley, California

94720, United States

(2) Environmental Energy Technologies Division,

Lawrence Berkeley National Laboratory, Berkeley, California 94720, United

States

and Department of Chemical and Biomolecular Engineering,

University of California, Berkeley, California 94720, United States

(3)

Materials Sciences Division, Lawrence Berkeley National Laboratory, Berkeley,

California 94720, United States

(4) The Advanced Light Source, Lawrence

Berkeley National Laboratory, Berkeley, California 94720, United

States

(5) Department of Physics,

Tsinghua University, Beijing 100084, China

M.R. is a visiting researcher

from South China University of Technology.

L.Z. is a visiting researcher

from University of Science and Technology of China.

Received: July 25, 2011

18523

dx.doi.org/10.1021/ja206955k |J. Am. Chem. Soc. 2011, 133,

18522–18525

Journal of the

American Chemical Society COMMUNICATION

[6.3.3A.1] 「RLSB」のシステム

[Ⅰ] ABSTRACT

(1) The loss of sulfur cathode material as a result of polysulfide

dissolution causes significant capacity fading

in rechargeable

lithium/sulfur cells.

(2) Here, we use a chemical approach to immobilize

sulfur and lithium polysulfides via

the reactive functional groups on

graphene oxide.

(3) This approach enabled us to obtain a uniform and

thin (around tens of nanometers) sulfur coating

on graphene oxide sheets

by a simple chemical reactiondeposition strategy and a

subsequent

low-temperature thermal treatment process.

(4) Strong interaction between

graphene oxide and sulfur or polysulfides enabled us

to demonstrate

lithium/sulfur cells with a high reversible capacity of 「950-1400 mA h/ g」,

and stable

cycling for more than 50 deep cycles at 「0.1C」 (1C = 1675 mA/ g).

[Ⅱ] DESCRIPTION

(1) Elemental

sulfur (S) is very attractive as a cathode material for high-specific-energy

rechargeable

lithium batteries, because a battery based on the

lithium/sulfur (Li/S) couple would yield a

theoretical specific capacity

of about 「1675 mA h/ g」 with a

theoretical specific energy of 「2600 W h/

kg」 on the assumption

of the complete reaction of Li with S to form Li2S.

(2) In addition, S is also inexpensive, abundant, and nontoxic.

(3) Therefore, S is a promising cathode material for high specific

energy Li/S batteries.(1-15 )

(4) Despite

these considerable advantages, there are still a number of challenges in Li/S

batteries.

(5) The first one is the high electrical resistivity of

elemental S.

(6) The second one is the high solubility (in organic

solvent electrolytes) of the polysulfide

ions that are formed during the

discharge/charge processes.

(7) The soluble intermediate Li polysulfides

can diffuse through the electrolytetothe

Li anode wherethey are reducedto

form solid precipitates (such as Li2S or Li2S2).

(8) These reduced

products can also diffuse back to the cathode during recharging.

(9) These issues can lead to low active materials utilization, low

coulombic efficiency, and short cycle

life of the S electrode.(1-15)

(10) In

order to address these challenges, various carbon and conductive polymer

materials have been used to

accommodate S, to overcome its insulating

property and reduce the

dissolution of Li polysulfides, as reported by

「Nazar」, et al.(1,13,15 )and others.(4,6,7,10,12,16-22)

(11) The most

recent work by 「Archer」 et al. demonstrated that the mesoporous carbon/S

nanocomposites can

be cycled for 100 cycles at 「974 mA h/ g 」at a rate

of 「0.5C (1C =1675 mA /g)」

with the corresponding coulombic efficiency

of ∼96% and 94%, respectively,

at the first and 100th cycles.(23)

(12) Despite this progress, there are still few reports on fabricating

novel CS

cathodes via the chemical reaction

approach.(14)

(13) In this work, we used a low-cost and environmentally

benign

chemical reaction deposition strategy to immobilize S on

quasi two-dimensional

graphene oxides (GO) to prepare graphene oxide sulfur

(GO-S) nanocomposite cathodes

for

Li/S cells

in 「ionic liquid-based electrolytes」.

(14) We first deposited

nano-S onto graphene oxide (GO) sheets by chemical reaction in a

microemulsion

system (see experimental section in the Supporting

Information [SI] for details).

(Supporting Information is not

quoted here.)

(15) Then,

we heat treated the assynthesized samples in an argon (Ar) environment at

low

temperature (155 C) for 「12 h」 in order to remove some of the

bulk S

which is not directly attached to the 「GO」 layers.

(16) When the

as-synthesized 「GO-S」 nanocomposites were heat-treated in Ar,

the bulk S on

the external surface of the 「GO」 melted and diffused

into the pores of the

「GO」 due to the strong adsorption effects

derived from both the high

surface area and the functional groups

on the surface of the 「GO」.

(17) At the same time, this low-temperature heat treatment process can

partially remove and/or chemically

modify some of the functional groups on the 「GO」 surface

and improve the electronic conductivity

of the as-prepared

「GO-S」 nanocomposites

(see Table 1 in the SI).

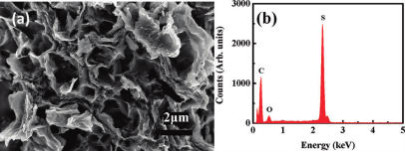

(18) 「Figure 1a」 shows the scanning electron

microscope (SEM)

image of the as-prepared 「GO-S」 nanocomposite after heat

treatment.

(19) The layer-like extremely conjugated nanostructures

with

highly developed porous structures are clearly illustrated.

(20) The energy-dispersive X-ray (EDX) microanalysis in (Figure 1b)

con-firms the existence of S in the composite.

(21) As indicated in the

thermogravimetric analysis (TGA), about 66 wt % S is incorporated

into the

GO

after heat treatment (Figure S1, SI: not quoted).

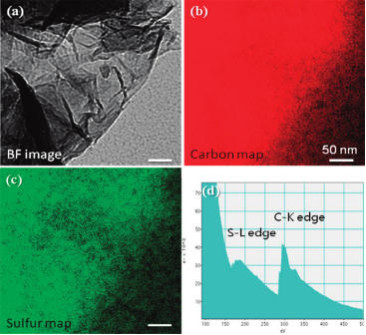

(22) The transmission

electron microscope (TEM) image in (Figure 2a) and

the electron

energy-loss spectrum (EELS) in (Figure 2d) indicate that

a thin layer of S

with a thickness of tens of nanometers is

homogenously dispersed on the

flake-like 「GO」 surface with no

significant fraction of bulk S exposed on

the external surface of the

sample after heat treatment

(For comparison,

see the SEM

images for pure 「GO」 and SEM/TEM images for 「GO-S」

nanocomposites in

Figures S2 and S3 (SI) before heat

treatment ; not quoted).

(23) The

corresponding elemental mapping of carbon (Figure 2b), and S (Figure 2c)

display

a very similar intensity distribution, revealing a homogeneous

S

coating on the 「GO 」flakes in the as-formed 「GO-S」 nanocomposites.

(24) The

unique structure of the 「GO-S」 nanocomposite can improve

the overall

electrochemical performance when it is used as a cathode material for Li/S

batteries.

(25) First, it can accommodate the significant volume changes of S as

it is converted to Li2S on

discharge, and back to elemental S on

recharge.(110,17,24 )

(26) In

addition, the partially reduced 「GO」 with its large surface area

along with

ubiquitous cavities can establish more intimate

electronic contact with S and

avoid aggregation and loss of

electrical contact with the

current collector.

(27) Second, the lowtemperature heat-treated 「GO」 still contains various kinds of

functional groups (Figure S5, SI).

(28) These functional groups can have strong

adsorbing ability to anchor S atoms and to effectively

prevent the

subsequently formed Li polysulfides from dissolving

in the electrolyte during

cycling.

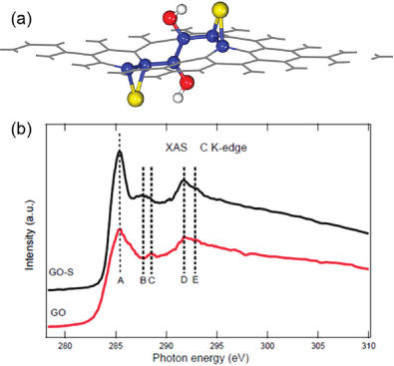

(29) We performed ab initio calculations to clarify the role

of

functional groups on 「GO」 in immobilizing S (see the calculation

methods

and detailed results in the SI).

(30) The results indicated that

both epoxy

and hydroxyl groups can enhance the binding of S to

the CC bonds due to the

induced ripples by the functional

groups (Figure 3a).

(31) We also performed soft

X-ray absorption

spectroscopy (XAS) measurement which probes unoccupied

electronic

structure and thus is a powerful tool for probing chemical bonding

in surface chemistry.

(32) (Figure 3b) shows the carbon K-edge

absorption

spectra for both 「GO」 and 「GO-S」

nanocomposites

(see S K-edge spectrum in Figure

S7, SI ; not quoted).

(33) The absorption features “A”,

“D”, and

“E”, which can be attributed to the π* state, excitonic state, and

σ*

state,25 are observed for

both samples.

Of note in the spectra

is the

increase in the sharpness of the π* and excitonic state for

GOS

nanocomposites as compared with GO, suggesting that the ordering of the

sp2

-hybridized carbon

structure is better formatted after S is

incorporated.

(34) In addition, feature “C” originating from a different

functional group (possibly the CO bond)

on the GO are weakened

significantly when incorporated with S,

which means strong chemical

interaction between S and the

functional group of 「GO」 happens

and S can partially reduce the

「GO」.(26)

(35) Besides,

a new feature “B”, originating from the CS σ*

excitations,27 is observed

for the 「GO-S」 nanocomposites.

(36) We

evaluated the electrochemical Li storage capability of these heat-treated 「GO-S」

nanocomposites

as potential cathode materials for Li/S cells in the

n-methyl-(n-butyl) pyrrolidinium bis-

(trifluoromethanesulfonyl)imide

(PYR14TFSI), Li-bis(trifluoromethylsulfonyl)imide

(LiTFSI), and

poly(ethylene glycol)

dimethyl ether (PEGDME, Mw =

250) mixture-based

electrolyte.

(37) (Figure 4a) shows the cyclic voltammetry (CV) profile of

one electrode.

(38) The measurement was conducted at a scan rate of 0.05

mV s1 in the voltage range of 1.0 to 3.6 V vs Li/Li+.

(39) During

the first cathodic scan, three main reduction peaks at around 2.4, 2.1, and 1.8

V were clearly shown.

(40) According to the reported mechanisms for oxidation and

reduction of S during discharge/

charge,(5,6,10,18,19,2831) the peak at

around 2.4 V can be assigned

to the reduction of elemental S to higher-order

Li polysulfides (Li2Sn, n ≧8).

(41) The

peak at about 2.1 V probably corresponds to

the reduction of higher-order Li

polysulfides to lower-order Li

polysulfides (such as Li2S6, Li2S4) from

Li2S8. (5,6,10,16-21,28-31)

(42) The

peak at 1.8 V is related to the reduction of polysulfide species to form Li2S.

(43) In the subsequent anodic scan, only one sharp oxidation peak is observed at

about 2.6 V that is attributed to the

complete conversion of Li2S and

polysulfides into elemental S.

(44) The main reduction peak is shifted to slightly

higher potential

and the oxidation peaks to lower potentials with increase in

cycle

number, indicating an improvement of reversibility of the cell with

cycling.

(45) In addition, as the cycle number increased, the oxidation peak at

2.6 V becomes less significant,

while another new one at 2.35 V grows higher

in intensity.

(46) The oxidation peak at 2.35 V is associated with the formation

of Li2Sn (n > 2).(23,29)

(47) After the second cycle, both the CV peak

positions and peak

currents undergo very small changes, indicating relatively

good capacity retention.

(48) The CV results show that 「GO」 can help to

prevent

S from dissolving into the electrolyte because of its large

surface along

with some functional groups on the surface.

(49) Figure 4b depicts the first and

second cycle discharge/charge

typical voltage profiles of the electrodes at

the 「0.02C rate (1C = 1675 mA/ g) 」between 1.0 and 3.0 V.

(The capacity values

in this article are calculated according to the mass of S.)

(50) All the

discharge curves show three plateaus in the voltage profile that

are

consistent with the peaks in the CV and are also well

documented in the

literature.(5,6,10,16,18-21,23,28)

(51) The GO-S nanocomposite delivers a high

initial discharge capacity of about

「1320 mA h/ g」 at「 0.02C」.

(52) The

corresponding coulombic effi-ciency in the first discharge/charge cycle is

96.4%.

(53) At the second cycle, a large reversible capacity of about 「1247 mA h/

g」 is

preserved (97.5% coulombic efficiency), corresponding to about 94.5%

capacity retention.

(54) This initial capacity loss is small compared

to the

formerly reported results of similar materials,(16,32) indicating

that the

strong 「GO-S」 interaction can reduce the dissolution of the

lithium

polysulfides into the electrolyte and thus minimize the shuttle phenomenon.

(55)

(Figure

4c) shows the cycling performance of the same cell cycled at a rate of 「0.1C」

after the initial two cycles at 「0.02C」.

(56) The discharge capacity of the

first cycle at 「0.1C」 remains at around 「1000 mA h/ g」.

(57) At the second cycle at

0.1C, this value decreases to about「 950 mA h/ g」.

(58) However, after more than 「50

cycles」 at the same rate, the reversible capacity remains at 「954mA h /g」

(with

a coulombic efficiency of about 96.7%), indicating

very stable reversibility

of the electrochemical reactions and excellent

capacity retention (also see

the cycle performance of another coin cell in Figure S10, SI).

(59) The

GO-S nanocomposites display improved coulombic efficiencies compared to the

former reports.23

(60) The discharge capacity of the GO-S was highly reproducible

over many coin cells.

(61) Another

example of the electrochemical

performance of the 「GO-S」 electrode is

demonstrated in (Figure 4d)

where a cell showed a reversible capacity of 「735 mA

h /g」 at「 0.5C」 after「 30 cycles 」at various rates.

(62) Further cycling at a low rate

of 「0.05 C」 brings it back to a reversible capacity of about「 1100 mA h/ g」

for

another 「20 cycles」.

(63) When this coin cell was discharged at a higher

rate of 「1C」, a reversible capacity of about 「550

mA/ g」 was obtained.

(64) The

last decrease of the rate to 「0.2C」, yielded a reversible capacity of about 「890 mA

h/ g」.

(65) When this coin cell was further discharged at 「2C」, an acceptable

reversible capacity of

about 「370 mA h/ g」 was obtained, indicating excellent

capacity reversibility and high rate performance

(see

the

corresponding discharge/charge profiles

in Figure S11, SI.; not quoted)

(66) The 「GO」 clearly performs very

well as a means to stabilize the S electrode.

(67) The 「GO」 provides highly

reactive functional groups on

its surface that can serve as immobilizers to

hold the S.(1,5,8)

(68) Also, by limiting the concentration of the polysulfide

anions in the

electrolyte, the redox shuttle phenomenon is largely

avoided.(1,8,9)

(69) The intimate contact of the S provided by the large surface

area

and the functional groups on 「GO」 is favorable to good electron/

ion

accessibility, leading to enhanced cycle performance and rate

capability.(19,17,20)

(70) In addition, the optimized

「ionic liquid-based electrolytes」 which have suitable viscosities and wetting

properties

influence the penetration of electrolyte into the S electrode

structure,

while increasing the ionic conductivity within the

electrodes at the

same time

(see control experiment in LiTFSIPEGDME-based electrolyte in

Figure S12,

SI ; not quoted).(5,33,34)

(71) In summary, a novel chemical approach is employed

to synthesize a 「GO-S」 nanocomposite

to immobilize S in

the cathode material of Li/S cells.

(72) The 「GO-S」 nanocomposite cathodes display good reversibility,

excellent capacity stability

of about 「1000 mA h/ g」, and rate capability

of up to 「2C」 in ionic liquid-based electrolyte.

(73) The 「GO」 in the

heat-treated composites has good conductivity and an extremely high surface

area, and

provides a robust electron transport network.

(74) The

functional groups on the 「GO」 surface play the role of immobilizers that

keep

intimate contact of the conducting matrix with S species,

and

effectively confine any polysulfides from dissolving.

(75) The 「GO」 network

also accommodates the volume change of the electrode

during the LiS

electrochemical reaction.

(76) As

a result, reversibility and high rate discharge capability were obtained.

(77) The same strategy could be helpful to explore and develop new

porous

carbon(35,36) or conductive polymer-based S nanocomposite cathodes

for advanced Li/S cells.

[Ⅳ] REFERENCES

(1)

Ji, X.; Lee, K. T.; Nazar, L. F. Nat. Mater. 2009, 8, 500–506.

(2) Hassoun,

J.; Scrosati, B. Angew. Chem., Int. Ed. 2010, 122, 2421–2424.

(3)

Kolosnitsyn, V.; Karaseva, E. Russ. J. Electrochem. 2008, 44, 506–509.

(4)

Yang, Y.; McDowell, M. T.; Jackson, A.; Cha, J. J.; Hong, S.

S.;

Cui, Y. Nano Lett. 2010, 10, 1486–1491.

(5)

Shim, J.; Striebel, K. A.; Cairns, E. J. J. Electrochem. Soc. 2002, 149,

A1321–A1325.

(6) Choi, Y.-J.; Chung, Y.-D.; Baek, C.-Y.; Kim, K.-W.; Ahn,

H.-J.;

Ahn, J.-H. J. Power Sources 2008, 184,

548–552.

(7) Liang, C.; Dudney, N. J.; Howe, J. Y. Chem. Mater. 2009,

21, 4724–4730.

(8) Ji, X.; Nazar, L. F. J. Mater. Chem. 2010, 20,

9821–9826.

(9) Gao, X.-P.; Yang, H.-X. Energy Environ. Sci. 2010, 3,

174–189.

(10) Lai, C.; Gao, X. P.; Zhang, B.; Yan, T. Y.; Zhou, Z. J. Phys.

Chem. C 2009, 113, 4712–4716.

(11) Ryu, H.-S.; Ahn, H.-J.; Kim, K.-W.; Ahn,

J.-H.; Lee, J.-Y. J. Power Sources 2006, 153, 360–364.

(12) Wang, J.; Yang,

J.; Xie, J.; Xu, N. Adv. Mater. 2002, 14, 963–965.

(13) Ji, X.; Evers, S.;

Black, R.; Nazar, L. F. Nat. Commun. 2011, 2, 325.

(14) Wang, H.; Yang, Y.;

Liang, Y.; Robinson, J. T.; Li, Y.; Jackson,

A.;

Cui, Y.; Dai, H. Nano Lett. 2011, 11, 2644–2647.

(15) He, G.; Ji, X.; Nazar,

L. Energy Environ. Sci. 2011, 4, 2878–2883.

(16) Cao, Y.; Li, X.; Aksay, I.

A.; Lemmon, J.; Nie, Z.; Yang, Z.; Liu, J.

Phys. Chem. Chem. Phys. 2011, 13,

7660–7665.

(17) Chen, S.-R.; Zhai, Y.-P.; Xu, G.-L.; Jiang, Y.-X.; Zhao,

D.-Y.; Li,

J.-T.; Huang, L.; Sun, S.-G. Electrochim. Acta 2011, 56,

9549–9555.

(18)

Jeon, B. H.; Yeon, J. H.; Kim, K. M.; Chung, I. J. J. Power Sources 2002, 109, 89–97.

(19) Liang, X.; Wen, Z.; Liu, Y.; Zhang, H.;

Huang, L.; Jin, J. J. Power Sources 2011, 196, 3655–3658.

(20) Wang, J.;

Chew, S. Y.; Zhao, Z. W.; Ashraf, S.; Wexler, D.; Chen,

J.; Ng, S. H.; Chou,

S. L.; Liu, H. K. Carbon 2008, 46, 229–235.

(21) Yuan, L. X.; Feng, J. K.;

Ai, X. P.; Cao, Y. L.; Chen, S. L.; Yang,

H. X. Electrochem. Commun. 2006, 8,

610–614.

(22) Wang, J.; Chen, J.; Konstantinov, K.; Zhao, L.; Ng, S. H.;

Wang,

G. X.; Guo, Z. P.; Liu, H. K.

Electrochim. Acta 2006, 51, 4634–4638.

(23) Jayaprakash, N.; Shen, J.;

Moganty, S. S.; Corona, A.; Archer,

L. A. Angew.

Chem., Int. Ed. 2011, 50, 5904–5908.

(24) Ji, L.; Tan, Z.; Kuykendall, T. R.;

Aloni, S.; Xun, S.; Lin, E.;

Battaglia, V.; Zhang,

Y. Phys. Chem. Chem. Phys. 2011, 13, 7170–7177.

(25) Skytt, P.; Glans, P.;

Mancini, D. C.; Guo, J. H.; Wassdahl, N.;

Nordgren,

J.; Ma, Y. Phys. Rev. B 1994, 50, 10457.

(26) Chen, W.; Yan, L.; Bangal, P.

R. J. Phys. Chem. C 2010, 114, 19885–19890.

(27) Pasquali, L.; Terzi, F.;

Montecchi, M.; Doyle, B. P.; Lukkari, J.;

Zanfrognini, B.; Seeber, R.; Nannarone, S. J. Electron Spectrosc.

Relat.

Phenom. 2009, 172, 114–119.

(28)

Yamin, H.; Peled, E. J. Power Sources 1983, 9, 281–287.

(29) Aurbach, D.;

Pollak, E.; Elazari, R.; Salitra, G.; Kelley, C. S.;

Affinito, J. J. Electrochem. Soc. 2009, 156, A694–A702.

(30) Jung, Y.; Kim,

S. Electrochem. Commun. 2007, 9, 249–254.

(31) He, X.; Pu, W.; Ren, J.; Wang,

L.; Wang, J.; Jiang, C.; Wan, C.

Electrochim. Acta 2007, 52,

7372–7376.

(32) Wang, J.-Z.; Lu, L.; Choucair, M.; Stride, J. A.; Xu, X.;

Liu, H.-K.

J. Power Sources 2011, 196, 7030–7034.

(33) Shin, J. H.;

Cairns, E. J. J. Power Sources 2008, 177, 537–545.

(34) Shin, J. H.; Cairns,

E. J. J. Electrochem. Soc. 2008, 155, A368–A373.

(35) Long, J. W.; Dunn, B.;

Rolison, D. R.; White, H. S. Chem. Rev. 2004, 104, 4463–4492.

(36) Ji, L.; Lin, Z.; Alcoutlabi, M.;

Zhang,

X. Energy Environ. Sci. 2011, 4, 268

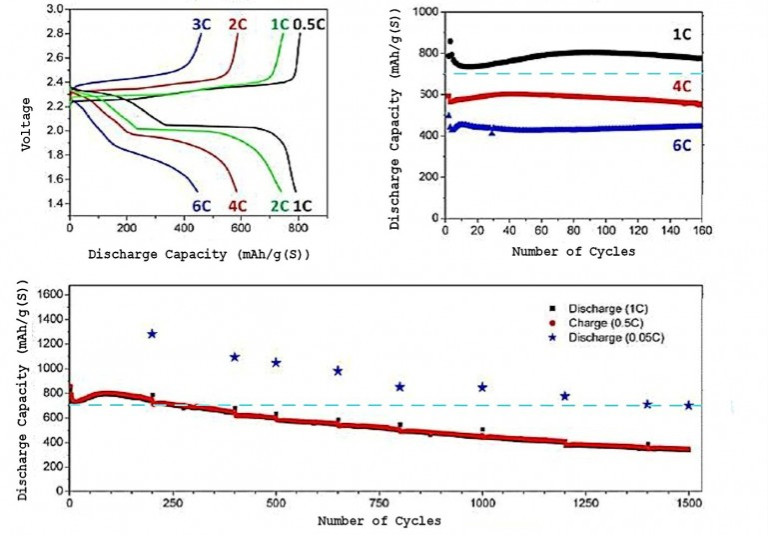

[6.3.3A.2] 結果

(1) 結果を図1、図2、図3、図4に示す。

図1 SEM image (a) and EDX spectrum (b) of the GO-S

nanocomposite

after heat treatment in Ar at

155

(This figure is quoted from the

document said above)

図2 TEM bright field (BF)

image (a) and the corresponding

elemental mapping for carbon

(b) and S (c) reveal a homogeneous S

coating on the GO flakes.

EELS spectrum is shown in (d).

The scale bars are 50

nm.

(This figure is quoted from the document said

above)

図3 (a) Representative

pattern of GO immobilizing S.

The hydroxyl enhances the

binding of S to the CC bond due to the

induced ripples by

epoxy or hydroxyl group.

Yellow, red, and white

balls denote S, O, and H atoms, respectively,

while the

others are C atoms.

Note that the C atoms bonding to S or O

are highlighted as blue balls.

(b) C K-edge XAS spectra of GO

and GO-S nanocomposites after heat

treatment in Ar at 155 C

for 12 h.

(This figure is quoted from the document said

above)

図4 (a) CV curve at

0.05 mV s1 scanning rate;

(b) galvanostatic discharge/charge

profiles at 0.02C rate;

(c) cycling performance at a constant

current rate of 0.1C after initial activation processes at

0.02C

for two cycles;

(d) reversible capacity

vs current density (rate capability).

The GO-S nanocomposites

were heat treated in Ar environment at 155 C for 12 h.

(This figure is quoted from the document said

above)

[6.3.3A.3] 評価

(1) 「グラフェン・オキサイド」の効果が主張されている。

(2) 「電流レート」が「2C」だと「400mAh/g」まで容量が落ちるからまだ実用的ではない。

[6.3.4A] 研究例(4A)

Energy & Environmental Science Issue 10,

2014

Improved lithium–sulfur batteries with a conductive coating on the separator to

prevent

the accumulation of inactive S-related species at the cathode–separator

interface

Hongbin Yao,(a) , Kai Yan,(a), Weiyang Li,(a),

Guangyuan Zheng,(b), Desheng Kong,(a),

Zhi Wei Seh,(a), Vijay Kris Narasimhan,(a), Zheng

Lianga and Yi

Cui,(a,c)

Energy & Environmental Science, 2014,7,

3381-3390

DOI:

10.1039/C4EE01377H

Received 03 May 2014, Accepted 14 Jul

2014

First published online 07 Aug

2014

[6.3.4A.1] 「RLSB」のシステム

(1) Improved

lithium–sulfur batteries with a conductive coating

on the separator to

prevent the accumulation of inactive S-related species

at the

cathode–separator interface bottom

(2) Lithium–sulfur (Li–S) batteries

are highly attractive for future generations of portable electronics

and electric vehicles due to their high energy density

and potentially low cost.

(3) In the past decades, various novel

electrodes and electrolytes have been tested

to improve

Li–S battery performance.

(4) However, these designs on electrodes

and electrolytes have not fully addressed the problem

of

low cycling stability of Li–S batteries.

(5) Here, we show the role

of the separator in the capacity decay of the Li–S battery,

namely that it can accommodate a large amount of

polysulfides inside which then precipitates

as a thick

layer of inactive S-related species.

(6) Using a thin conductive

coating on the separator to prevent the formation of the inactive

S-related species layer, we show that the specific

capacity and cycling stability

of

the Li–S battery are both improved significantly compared to the

battery with a pristine separator.

(7) Combining this separator design with a monodisperse sulfur

nanoparticle cathode,

we show Li–S batteries with

a life of over 「500 cycles」 with an initial specific capacity

of 「1350 mA h/ g」 at「 C/2」 and a cycle decay as

low as 「0.09% 」per cycle.

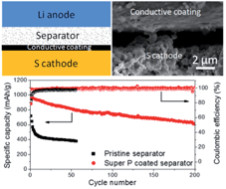

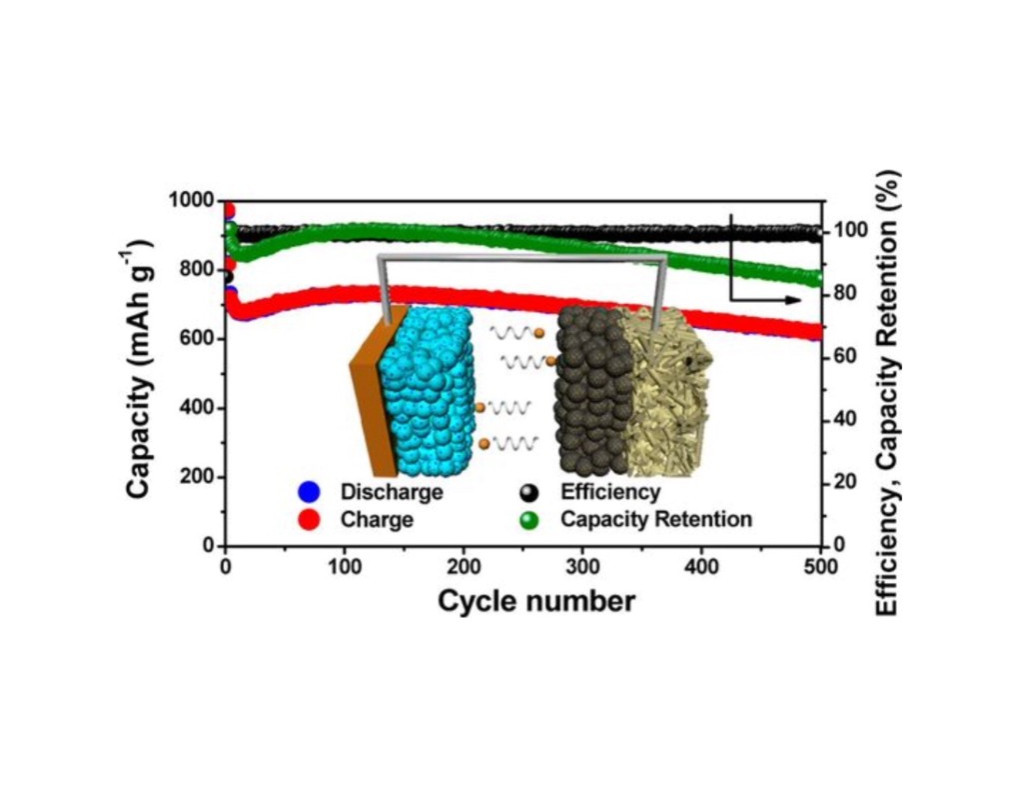

[6.3.4A.2] 結果

(1) 結果を図1に示す。

図1

(This figure is quoted from the document said

above)

(2) 「電流レート」は「0.5C」である。

(3) 「500サイクル」の後でも「1350mAh/g」の容量を維持しており、 「0.09%」しか劣化していない。

(4) かなり実用的レベルに達しているのではないか?

*******

A PART END ********

[6.3.1] 研究成果(1)

Improving lithium-sulfur batteries for

greater energy density

(September

26, 2014) Paul

Dvorak

[6.3.1.1] 「RLSB」のシステム

(1) This article comes from

Nano Letters and will be of interest to who wish to stabilize their grids.

A search for the next great

high-energy, rechargeable battery technology has been on for a while.

(2) Recently, scientists report they have overcome key obstacles toward

making lithium-sulfur (Li-S) batteries,

which have potential to

outperform today’s lithium-ion technology.

(3) This study appears in the

ACS journal Nano Letters.

(4) To better confine the sulfur/polysulfides

in the electrode of lithium–sulfur (Li/S) batteries

and improve the

cycling stability, we developed a double-layered core–shell structure

of

polymer-coated carbon–sulfur.

(5) Carbon–sulfur was first prepared

through the impregnation of sulfur into hollow carbon spheres

under

heat treatment, followed by a coating polymerization

to give a

double-layered core–shell structure.

(6) From the study of scanning

transmission electron microscopy images,

we demonstrated that the sulfur

successfully penetrated through the porous carbon shell

and aggregated

along the inner wall of the carbon shell, which, for the first time,

provided visible and convincing evidence that sulfur preferred diffusing

into the hollow carbon rather

than aggregating in/on the porous wall of

the carbon.

(7) Xingcheng Xiao, Weidong Zhou, Mei Cai

and colleagues point out that the capabilities of lithium-ion batteries,

which power many of our consumer electronics, as well as electric

vehicles, have largely plateaued.

(8) Scientists have been pursuing a

number of new battery technologies to topple today’s standard.

(9) One

heavy focus has been on a key battery component that is currently made out of a

metal oxide.

(10) Some researchers have been trying to replace the metal

oxide with cheaper and lighter sulfur,

to make Li-S batteries.

(11) In theory, this could allow batteries to pack five to eight times

the energy of existing technology.

(12) One of the main problems with

this approach, however, is that Li-S compounds escape from where

they’re supposed to be, which causes the battery to lose charge

quickly.

(13) The team set out to find a way to contain the errant

compounds.

(14) To solve the problem, the researchers made tiny, hollow

shells out of carbon, which is conductive.

(15) They then coated them

with a polymer to help confine the Li-S compounds inside.

(16) When

tested, the structures kept up a high-energy storage capacity

(630

mAh/g versus less than 200 mAh/g of lithium-ion batteries) over 600 cycles

of fast charging and discharging.

(17) “These results provide

promising insights and novel concepts for future sulfur-based batteries,”

the researchers conclude.

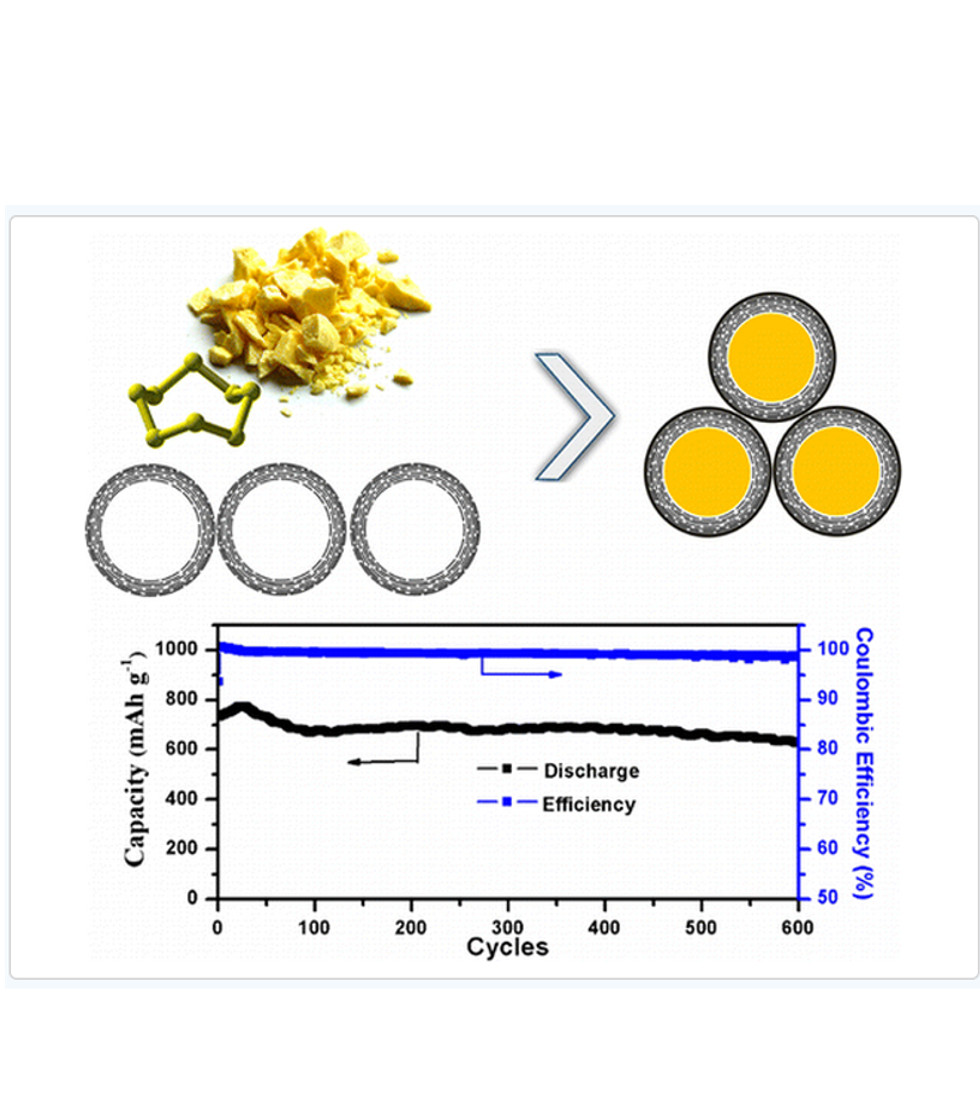

[6.3.1.2] システムの特徴

(1) 「正極」の「硫黄」を被覆している。

[6.3.1.3] 結果

(1) 結果を図1に示す。

図1

(THIS FIGURE IS QUOTED FROM THE DOCUMENT SAID ABOVE)

(2) 「600サイクル」で「600mAh/g」の容量を維持している。

(3) 電流レートは「0.6C」と思われる。

[6.3.2] 研究成果(2)

Dr. Vasant Kumar at the University of Cambridge and

Professor Renjie

Chen at the

Beijing Institute of

Technology

Graphene sheet-sulfur/carbon composite cathode

for higher performance Li-sulfur batteries

(16 December 2014)

[6.3.2.1] リチウム硫黄電池のシステム

(1) A team of researchers led by

Dr. Vasant Kumar at the University of Cambridge and Professor Renjie Chen

at the Beijing Institute of Technology has devised a three-dimensional

hierarchical sandwich-type

graphene sheet-sulfur/carbon (GS-S/CZIF8-D)

composite to address performance-related issues

in

Lithium-sulfur batteries such as low efficiency and capacity

degradation.

(2) The thin graphene sheet, wrapped around the sulfur/zeolitic

imidazolate framework-8

derived carbon (S/CZIF8-D) composite, has

excellent electrical conductivity and mechanical flexibility.

(3) This

facilitates rapid electron transport and accommodates the changes

in volume of the sulfur

electrode.

(4) Compared with an unwrapped S/CZIF8-D sample, Li-S

batteries with the GS-S/CZIF8-D

composite cathode showed enhanced

capacity, improved electrochemical stability up to 120 cycles,

and

relatively high Coulombic efficiency.

[6.3.2.2] 条件

(1) 「硫黄」を閉じ込めている。

[6.3.2.3] 結果

(1) 結果を図1に示す。

図2-F

(THIS FIGURE IS QUOTED FROM THE DOCUMENT SAID ABOVE)

図1

(THIS FIGURE IS QUOTED FROM THE DOCUMENNT SAID ABOVE)

(2) 「120サイクル」で「700mAH/g」の容量を維持している。

(3) 電流レートは不明。

[6.3.3]

研究成果(3)

A

highly efficent polysulfide mediator for lithium-sulfur

batteries

Nature Communications Vol.6, Article;

5682

DOI: 10.1038/ncomms6682 REceived 23 Sep ,2014,

Acc 27 Oct. 2014, Pub 06 Jan

2015

(Department of Chemistry, University of Waterloo,

200 University Avenue West, Waterloo,

Ontario, Canda, N2L 3G1)

Xiao Liang, Connor Hart, Quan Pang & Linda F.

Nazar

(BASF SE, 67056

Ludwigshafen,Germany)

Arnd Garsuch, Thomas

Weiss

[6.3.3.1] リチウム硫黄電池のシステム

(1) The lithium–sulfur battery is

receiving intense interest because its theoretical energy density

exceeds that of lithium-ion batteries at much lower cost, but practical

applications are still hindered

by capacity decay caused by the

polysulfide shuttle.

(2) Here we report a strategy to

entrap polysulfides in the cathode that relies on a chemical process,

whereby a host—manganese dioxide nanosheets

serve as the prototype—reacts

with initially formed lithium

polysulfides to form surface-bound intermediates.

(3) These function as

a redox shuttle to catenate and bind ‘higher’ polysulfides, and convert them

on reduction to insoluble lithium sulfide via disproportionation.

(4) The sulfur/manganese dioxide nanosheet

composite with 75 wt% sulfur exhibits a reversible

capacity

of 1,300 mA h g−1 at moderate rates and a fade

rate over 2,000 cycles of 0.036%/cycle,

among the best reported to

date.

(5) We furthermore show that this mechanism extends to graphene

oxide and suggest it can be

employed more widely

[6.3.3.2]

結果

(1) 結果を図1に示す。

図1

(THIS FIGURE IS QUOTED FROM THE

DOCUMENT SAID

ABOVE)

(2) 「2C」で「200サイクル」で「600mAh/g」の容量を維持している。

(3)

「600mAh/g」の容量は現行の「リチウムイオン電池」の「4倍」もある。

(4) 「リチウム硫黄電池」では「電圧」が「半分」であるから「重量エネルギ密度」は「2倍」である。

[6.3.4] 研究成果(4)

A group of researchers led

by Professor Lee Jae-young

at the Gwangju Institute of Science and

Technology

The results of the development were published in the

online version of ChemSusChem on April 29

with the title of

“Improvement of energy capacity via Vitamin C-treated dual-layered

graphene-sulfur cathodes

in lithium sulfur battery”.

[6.3.4.1] システム

(1) 「正極」の構造を工夫している。

(2) Researchers develop 20% improved lithium-sulfur

battery for electric cars using vitamin C

may 15, 2015 by admin leave a

comment

(3) Korean researchers have developed a new type of lithium–sulfur battery

using 「vitamin C」 with a 20% improvement in performance over current ones.

(4) A group of researchers led by Professor Lee Jae-young at the Gwangju

Institute of Science and Technology

said on Thursday that they succeeded in

improving the energy capacity of lithium–sulfur batteries

with vitamin C

treated dual-layered graphene–sulfur.

(5) 「Lithium-sulfur batteries」 are widely considered as a viable replacement for

current 「lithium-ion batteries」

for electric cars because of its superior

energy density.

(6) Yet, 「lithium-sulfur batteries」 have not been actively used in

the field yet since there are

a few problems to be resolved such as poor

cycle performance and low charge/discharge rates.

(7) However, the researchers showed that their 「vitamin C treated dual-layered

cathode」,

which is composed of a 「sulfur active layer」 and a 「polysulfide

absorption layer」,

can increase sulfur utilization dramatically resulting in

a lithium-sulfur battery with a high specific capacity

of over

「600 mAh/g(sulfur)」 after 「100 cycles」 even under a high current rate of 「1C」.

(8) Professor Lee said,

“This development is meaningful in a sense that it

can greatly improve low cycle performance

of lithium-sulfur batteries, which

is a big obstacle to commercialization of them,”

“we expect the

new development will practically increase the adaptation of lithium-sulfur

batteries to next-generation electric car batteries.”

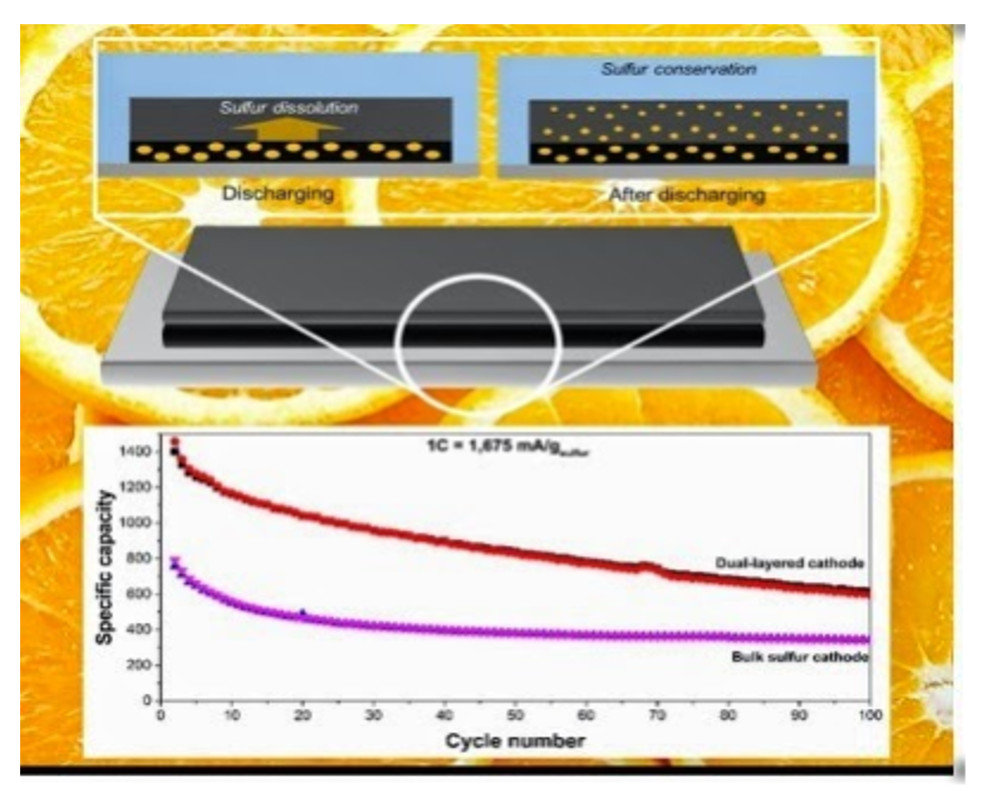

[6.3.4.1] 研究結果

(1) 図1に研究結果が示されている。

図1

(THIS FIGURE IS QUOTED FROM THE DOCUMENT SAID ABOVE)

(2) 電流レートは「1C」でのデータである。

(3) 「100サイクル」で「600mA/g(sulfur)」の容量であるが、サイクルとともに

劣化傾向を示している。

[6.3.5] 研究成果(5)

New

Lithium-Sulfur Battery With Cycle Performance Comparable To That Of

Lithium-Ion Batteries & Double The Energy

Density

Clean Technology Wednesday, April 15, 2015

[6.3.5.1] システム

(1) A new lithium-sulfur battery that demonstrates cycle

performance that's comparable to that

offered by currently available

commercial lithium-ion batteries and possesses roughly twice

the energy

density has been developed by an international team of researchers

from

South Korea and Italy.

(2) This research team — which was led by

researchers from 「Hanyang University」 —

utilized a highly reversible

「dual-type sulfur cathode 」(solid sulfur electrode and polysulfide catholyte)

and a 「lithiated Si/SiOx nanosphere anode」, in order to achieve its new

results.

(3) A new research paper from the group explained that the new

lithium-sulfur battery

delivered a specific capacity of ∼「750 mAh /g」

over 「500 cycles 」(85% of the initial capacity).

(4) The reason for the

impressive new results (possibly), according to those involved,

is as a

result of a synergistic effect between the enhanced electrochemical performance

of the new anode and the optimized layout of the cathode.

(5) While the new work won’t result in lithium-sulfur batteries replacing

lithium-ion ones tomorrow,

it does bring the commercial viability of

the technology one step closer —

as the new work has addressed some of

the primary issues with the technology.

(6) The researchers designed a LiS cell using a dual-type hybrid sulfur

cathode

and a lithiated Si/SiOx nanosphere anode with an optimized

liquid electrolyte.

(7) The cathode consists of an activated

carbon−sulfur composite

on a gas diffusion layer (GDL) electrode in

contact with a catholyte solution

to which 「Li2S8」 has been added.

(8) This cathode system delivers a maximum capacity of ∼「1300 mAh /g」

with respect

to the overall mass of sulfur (about 1.2 mg) from both the

solid sulfur

(about 0.2 mg on the electrode) and the dissolved lithium

polysulfide

(1.024 mg in 80 μL of the polysulfide-containing

electrolyte).

(9) At a rate of 「C/3」, the cathode shows a capacity of ∼「1000 mAh/ g」;

Coulombic efficiencies of more than 99.3% except for the first cycle;

and a maintenance of the capacity above 99% of the initial capacity

even after 100 cycles.

(10) The 「lithiated Si/SiOx nanosphere anode」

used shows highly stable cycling behavior

over 「100 cycles」 with a

capacity of as high as 「800 mAh/ g」

and cycling efficiency approaching

100%.

(11) The full lithium-ion sulfur cell presented in the study

delivers a capacity

of ∼「750 mAh/ g」 with an average working voltage

of about 「1.8 V」,

corresponding to the energy density of 「497 Wh /kg」

based on the weight of active materials

on the cathode and anode.

(12) Very interesting.

While I personally don’t expect

lithium-sulfur batteries to replace lithium-ion batteries

anytime in

the near future for most applications (and never at all for some applications),

the technology does seem to be improving fairly rapidly.

It’ll be interesting to see how it ends up being utilized.

(13) The new findings were detailed in a paper published in the journal Nano Letters.

[6.3.5.2] 研究結果

(1) 図1に研究結果を示す。

図1

(THIS FIGURE IS KUOTED FROM THE DOCUMENT SAID ABOVE)

(2) 電流レートは 「C/3」のデータである。

(3) 「500サイクル」では「700mAh/g」の容量が得られている。

[6.3.6]

研究成果(6)

「イオン液体」を用いた次世代リチウム二次電池の構築

渡邉正義 横浜国立大学大学院工学研究院

[6.3.6.1] リチウム硫黄電池のシステム

(7) In previous Li-S battery designs, the

electrolyte used was liquid in nature.

(8) This proved a double-edged

sword:

the liquid electrolyte is an excellent conductor because of how

it dissolves the lithium compounds,

but this dissolution also causes

the battery to break down

prematurely.break down prematurely.

(9) The liquid electrolyte is

also flammable, posing serious safety concerns.

(10) But

now, researchers may have found a way around these problems.

(11) "Our

technology overcomes the capacity fade and safety issues of Li-S technology,"

Dr. Chengdu Liang, lead author of a paper on the research, told

Gizmag.

(12) "The battery still performs well after a few hundred

cycles, and the volumetric density could be

slightly better than

Li-ion batteries."

(14) Even

after 「 300 charge-discharge cycles」 at 「60°C (140ºF)」, the battery retained

a capacity of 「1200 mAh/g」, compared to the 「140-170 mAh/g」 of a

traditional 「lithium-ion battery」

(lithium-sulfur batteries, however,

only deliver about half the voltage of lithium-ions, so this 8-fold increase

actually translates into a 4-fold increase in energy density).

(15) The

battery uses elemental sulfur, which is a byproduct of industrial petroleum

processing.

(16) In other words, the battery could also provide a way

to recycle industrial waste into a useful – perhaps

even superior –

technology.

(17) "The

main limitation is the relatively low ionic conductivity of the solid

electrolyte,"

said Liang.

(18) "So the power density is lower

than Li-ion batteries, but it can be improved with a better solid electrolyte.

Moreover, the ceramic structure is brittle, and much optimization is

needed."

(19) The

technology is still in the early stages of development, but Liang and colleagues

are working on ironing out

these issue and have filed a patent

application for their battery design.

(20) The

paper detailing the study was recently published in the journal 「Angewandte Chemie」.

(21) Gizmag wrote back to Dr. Chengdu Liang

for more details of the battery's charging and discharging behavior.

(22) Here is his response:

(23) "We

did not observe self-discharge.

A charged cell was put on shelf for

over a week, and it still delivered the same capacity.

(24) The essence

of our all-solid battery design is to eliminate the self-discharge

through the all-solid configuration.

(25) "This

battery charges slower than Li-ion battery at the current status for a simple

reason;

the ionic conductivity of both the solid electrolyte and

cathode are not high energy

to have high current density.

Much better performance at elevated temperatures such as 60 degrees C

or higher."

[6.3.7.2] 成果

(1) 「300回」の充放電サイクルの後でも「60℃」において

「1200mAh/g」の容量を維持している。

(2) 現行の「リチウム・イオン電池」の「140-170mAh/g」の「電流容量」に比較して

「電流容量」では「8倍」であるが、「電圧」が「半分」であることを考慮すると、

「重量エネルギ密度」としては「4倍」になる。

(3) しかし「固体電解質」では「出力密度」は「リチウム・イオン電池」に比べて小さいのが課題である。

[6.3.8] 研究成果(8) Impressive

graphene-based cathode for lithium-sulfur

batteries

Graphene applications Batteries Technical / Research

Source: cleantechnica Apr 20, 2015

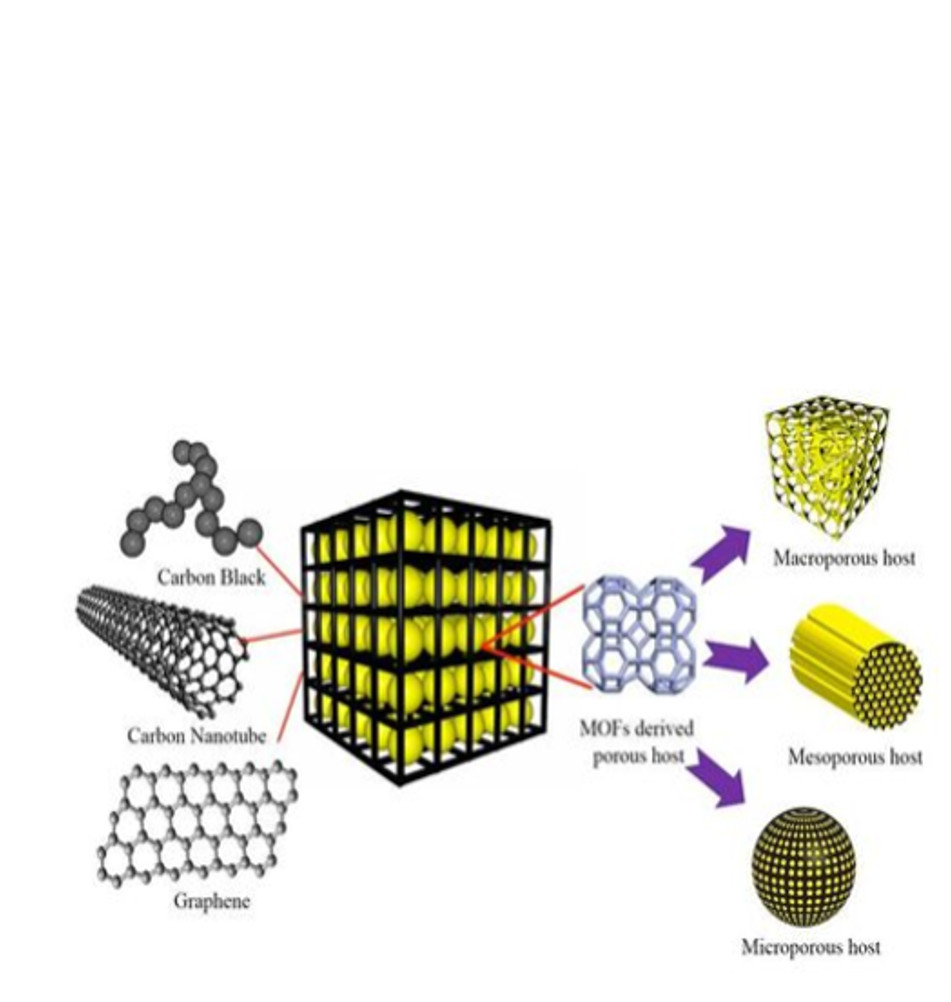

[6.3.8.1] リチウム硫黄電池のシステム

(1) Researchers at Beihang University in China developed

new cathode materials

for lithium-sulfur batteries, made from vertically

aligned sulfur–graphene (S-G) nanowalls

on electrically conductive

substrates.

Impressive cathode for lithium-sulfur batteries image

(2) These

new cathodes are reported to allow fast diffusion of lithium ions and electrons

and achieve an excellent capacity

(of 1261 mAh g–1 in the first

cycle, and over 1210 mAh g–1 after 120 cycles)

and high-rate performance

(more than 400 mAh g–1 at 8C, 13.36 A g–1).

(3) The scientists claim

that these impressive figures position it as the best demonstrated rate

performance

for sulfur-graphene cathodes.

(4) The researchers

believe that this new work may open the door to new approaches

to the

manufacture of graphene-containing composites with unique structures

“for catalysis, sensors, and energy storage and conversions.”

[6.3.8.2]

研究結果

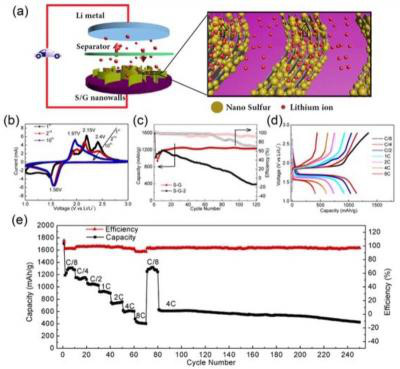

(1) 図1に結果を示す。

図1

(THIS FIGURE IS QUOTED FROM THE DOCUMENT SAID

ABOVE)

(2) 電流レートは「2C」で容量は「700mAh/g」もある。

(3) 充分に実用的レベルに達している。

(4) この「RLSB」を搭載した「EV」の「試作車」を走らせてほしい。

Célèbre beaux arts du

monde